Facilities - Foundry Facilities - Foundry |

|

Back to Facilities |

|

Steel Division Steel Division

|

Pattern :

- Well equipped pattern storing and repairing yard.

- 3D Modeling software for theoretical weight calculation.

- Types of pattern :

- Thermocol

- Wooden

- Aluminium

Pattern Shop

|

Match plate mounted Wooden Pattern |

Thermocol Pattern |

|

|

Moulding :

- Match plate mounted patterns.

- Max. mould box size : 4500mm X 1100mm X 450mm and 2600mm dia X 450mm.

- 2nos of Continuous sand mixer using alfa set binders.

- capacity : 20 MT/hr & 10 MT/hr

Moulding Shop |

Moulding Shop |

Pouring for steel casting |

|

|

Melting :

- 2nos of Induction furnace

- Capacity : 3MT, 2.5MT and 1.5MT(Dual crucible).

- Laddle capacity : 3MT, 4MT and 10MT with bottom pouring.

- Casting Capacity : 5MT Single Piece.

Melting Shop |

Melting Shop |

|

|

|

Heat Treatment :

- 5 numbers of heat treatment furnaces for Conventional Heat treatment.

- 4nos of Hanger type shot blasting m/cs

Heat Treatment Shop |

Heat Treatment Furnace |

Hanger type shot blasting Machine |

|

|

Through Hardening and Surface hardening :

- 3 numbers of gas carburising furnaces (capacity 760mm dia and 350kg & 1200mm dia and 3MT) for through as well as case hardening of Alloy steel castings.

Oil quenching and tempering

of alloy steel castings |

Sealed quench

furnace – 3 Nos. |

|

|

|

Fettling :

- Well equipped fettling shop with heavy duty swing frame grinders, Pneumatic chippers, Sanders and so on.

|

|

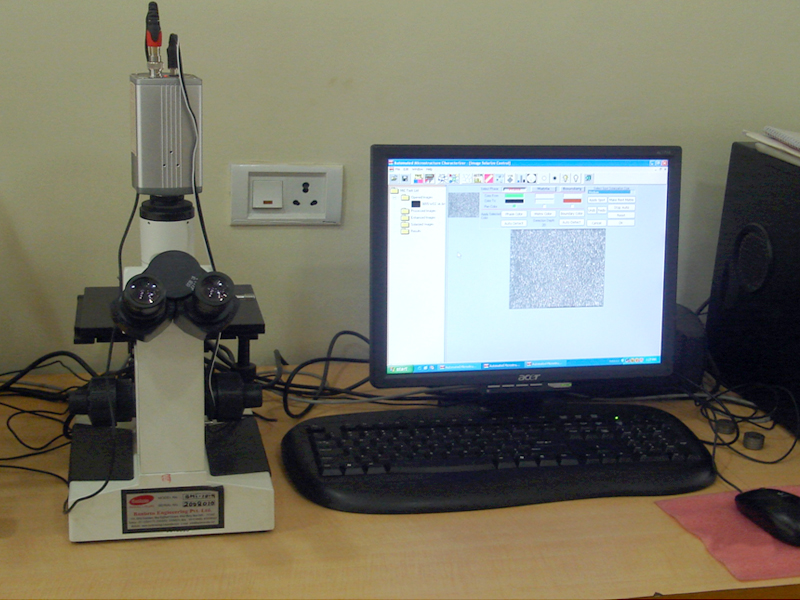

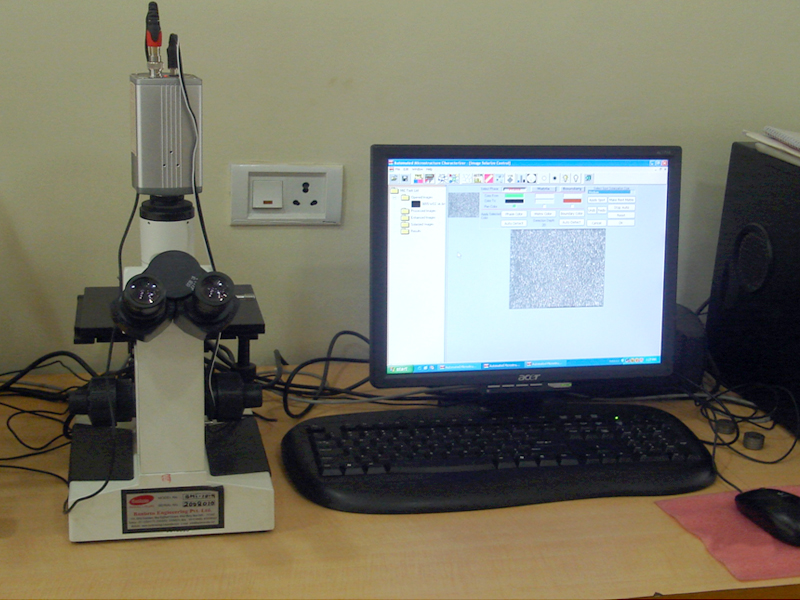

Quality Control :

- Spetrometer for chemical analysis

- Metallurgical microscope

- Vicker’s hardness testing machine

- Digital as well as poldy hardness testers

- Impact testing m/c and Universal tensile testing m/c.

- NDT facilities like DP, MPI, UT & RT

Metallurgical Laboratory |

Metallurgical Laboratory |

Metallurgical Laboratory |

Metallurgical Laboratory |

Metallurgical Laboratory

|

Metallurgical Laboratory |

Metallurgical Laboratory |

LPT testing of Mn.steel Gear Wheel |

MPI on Running Wheel

|

UT on C.S.Boss |

Straightening of Bucket Tooth |

Marking on Chain Sprocket |

|

|

Machining :

- Very well equipped machine shop with almost all types of machines.

- Also we are supported by our Engg. Division with over 200 CNC / NC machines.

CNC VTL |

CNC VTL |

CNC Lathes |

Lathe |

|

|

|

|

| |

Non – Ferrous Division Non – Ferrous Division |

Moulding :

- Centrifugal die casting, gravity die casting and conventional sand moulding for non ferrous castings.

Centrifugal Die Casting M/c

(2 m Dia) |

Pouring of Non-ferrous casting |

Table type Shot blasting M/c |

Degassing of Aluminium |

|

|

|

|

Melting :

- 3nos of induction furnaces of 300kg, 150kg and 100kg capacity

- 2nos of gas fired furnaces of 300kg and 200kg capacity.

- Single piece capacity : 150kg/pc for aluminium casting and 500kg/pc for copper base casting.

Gas fired furnace |

Induction furnace |

Tapping for non-ferrous casting |

|

|

Machining :

- Very well equipped machine shop with almost all types of machines.

- Also we are supported by our Engg. Division with over 200 CNC machines.

CNC VTL |

CNC Hobbing (Worm Wheel) |

CNC Lathes |

CNC VTL |

CNC Hobbing

|

Lathe |

| |

|

|

|

|